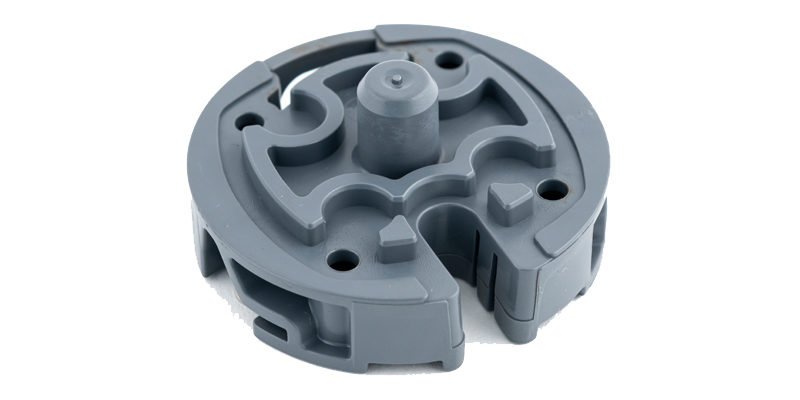

Plastic injection

With its location in the Ardennes, within a department and an area historically centred on metallurgy, CEVA has succeeded in placing thermoplastics materials as a real, practical alternative to metals.

With its location in the Ardennes, within a department and an area historically centred on metallurgy, CEVA has succeeded in placing thermoplastics materials as a real, practical alternative to metals.

As a specialist in plastic injection moulding for 20 years, we are most experienced in mono injection. Over the years, we have also successfully developed other technologies such as bi and tri-material injection and also overmoulding.

Notre équipement :

1 110-t press1 200-t press1 250-t press1 320-t press

Injection of two different materials simultaneously or sequentially from the same press and the same tooling, offers you the possibility of combining materials with specific technical and/or aesthetic characteristics on the same part.

We offer different technologies for these 2 types of injection:

Notre équipement :

1 x 110 t press1 x 200 t press1 x 250 t press2 x 320 t presses

As part of our drive for post-production optimisation, all our resources have been optimised to achieve maximum performance for our organisation: tools with in-line hot runners or granulators, Cartesian or six-axis robots on all our machines, sorting conveyors, etc.

Overmoulding is a process for combining several materials in a single injected part in the same mould. New functionalities can be added to the part by using several different materials.

1

Overmoulding can be used to provide protection for the overmoulded insert or a two-colour plastic part by combining two materials with a rigid part and a soft part.

2

This process gives an optimised cycle time and removes the risk of contamination between the different operations, and the different materials adhere together perfectly.

3

Overmoulding is performed in our works either manually or by robot using two presses operating in tandem.

4